Aluminium Sections

Types, Properties, Uses & Manufacturing Overview

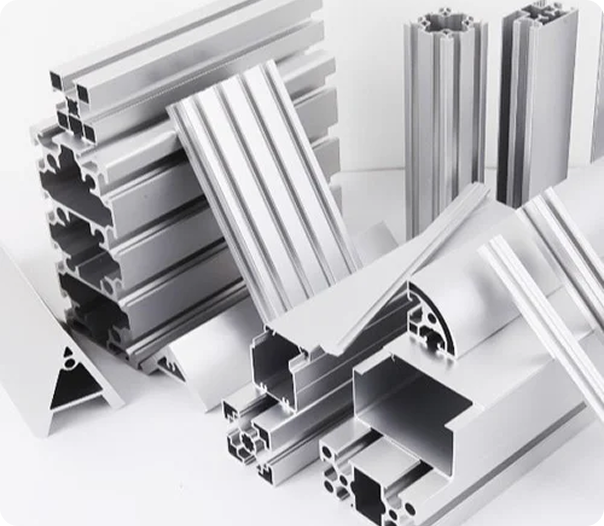

What Are Aluminium Sections

Aluminium sections are extruded profiles created with specific cross-sectional geometries designed to fulfill precise structural or functional roles. Unlike simple raw materials, these sections are engineered to distribute load effectively and integrate seamlessly into larger assemblies. They are generally categorized based on their complexity.

Solid Sections

Robust profiles without enclosed voids (e.g., flat bars, rods).

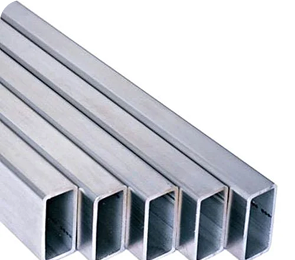

Hollow Sections

Profiles featuring one or more enclosed "cells" (e.g., tubes, square sections).

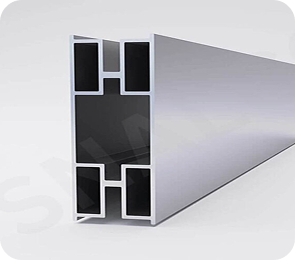

Semi-Hollow Sections

Partially enclosed profiles designed for specific interlocking or mounting functions.

Common Types of Aluminium Sections

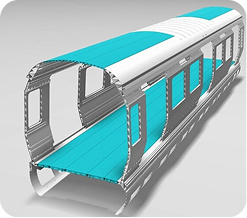

Aluminium section is one of the most widely used metal forming processes in modern manufacturing. It allows aluminium to be shaped into complex, uniform cross-sections that combine structural strength, dimensional accuracy, and long-term durability. Because aluminium is lightweight, corrosion-resistant, and recyclable, extruded aluminium components are used extensively across construction, infrastructure, transportation, electrical systems, renewable energy, and industrial machinery.

Square & Rectangular Hollow Section

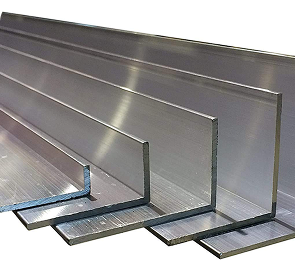

Angles, Channels, and T-Sections

Modular Framing Sections

Architectural and Decorative Sections

Applications of Aluminium Sections

Construction & Infrastructure

Industrial Engineering

Industrial automation frames

Retail & Display

Transport and logistics equipment

Manufacturing & Quality Standards

Aluminium Section Industry in India India has rapidly emerged as a global hub for aluminium section manufacturing, driven by massive infrastructure growth and a robust industrial sector. The industry benefits from an abundant domestic supply of high-grade aluminium and a sophisticated manufacturing ecosystem.

Common Aluminium Alloys Used in Extrusion

Straightening & Stretching

To ensure perfect alignment and remove internal stresses.

Precision Cutting

To meet exact project specifications

Surface Treatment

Including anodizing or powder coating to enhance durability and visual appeal.

Alloy Control

Utilizing specific series (like 6000 series) to balance strength and finish quality.

High Strength-to-Weight Ratio

Natural Corrosion Resistance

Machinability and Assembly

Thermal & Electrical Conductivity

Sustainability & Infinite Recyclability

Aluminium Section Industry in India

Aluminium Section Industry in India India has rapidly emerged as a global hub for aluminium section manufacturing, driven by massive infrastructure growth and a robust industrial sector. The industry benefits from an abundant domestic supply of high-grade aluminium and a sophisticated manufacturing ecosystem.

Modern extrusion facilities

Skilled technical workforce

Competitive production costs

Production Ecosystem

Growing export capabilities

About

Ratnashri

Ratnashri Aluminium is an ISO 9001:2015, ISO 14001:2015, and BIS certified manufacturer of aluminium extrusion products including solid and hollow profiles and sections, pipes, tubes, bars, rods, and billets. The company operates a modern manufacturing facility with imported machinery and in-house testing capabilities near Ahmedabad, supporting a wide range of industrial and architectural applications.